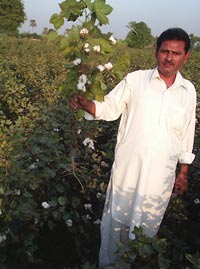

May 16, 2011: COTTON growers in lower Sindh especially in Sanghar district have suffered germination losses owing to questionable variety of seeds and very early crop sowing. Many of them are cultivating the crop afresh,

May 16, 2011: COTTON growers in lower Sindh especially in Sanghar district have suffered germination losses owing to questionable variety of seeds and very early crop sowing. Many of them are cultivating the crop afresh, incurring extra expenditure.

According to estimates of the agriculture department officials, 35 per cent of the area normally set for cotton crop has so far been brought under cultivation.

“The Federal Committee on Agriculture (FCA) has not set the target for the current year’s cotton production so far amidst report that agriculture is now a devolved subject and its job would be carried out by provincial agriculture departments.

For the same reason the FCA’s meeting has not been held as yet, says Amin Thebo, an official of the crop reporting services.

He says last year cotton was cultivated over a target area of 650,000 hectares in Sindh, but the unprecedented floods ruined the crop over a vast area on the right bank’s katcha and settled areas reducing it to 475,000 hectares.

There are various reasons behind the damage to the current crop such as unusual climatic conditions particularly northern winds, the unsuitable sowing period, and the quality of seed.

Sowing of cotton is recommended in early April in the lower region of Sindh. But in the current season, cotton growers started its cultivation as early as February and March after persuasion by seed providers, who claimed that early sowing would give a better yield.

“I myself opted for Tarzan-I variety of BT cotton which is an early maturing variety with 100 maund per acre yield. But the weather did not support the crop,” says Thebo. Growers had sown the seed in March but its germination was badly affected.

Sanghar is an important district for cotton production, and according to official figures, this district cultivates over 135,500 hectares. But the growers of the district are also complaining of huge losses owing to early sowing of the crop and are re-cultivating the crop.

In other cases, cultivators were filling the gaps in their lands where seed germination had been affected, and are incurring extra expenditure on seed, labour and other outputs. In several cases, growers were told to sow 701 seed, a variety of BT cotton that reportedly yields 100 maunds per acre, but it did not work and the growers suffered huge losses

“There is a tendency among many cotton growers that they do not clear their lands of cotton crop and keep them intact till the next Kharif season as clearing of cotton fields and preparing them for the Rabi wheat requires lot of investment. They keep picking cotton from the fields regardless of the quantity as even one maund of cotton per acre gives them reasonable income as compared to wheat,” says Haji Nadeem Shah of Matiari. The growers got Rs4,600 – 4775 per 40 kg for last year’s cotton, he added.

According to estimates, land preparation and per acre sowing of cotton requires between Rs30,000-35,000 including cost of diesel, tractor and pesticides. This year this will increase further in view of recent hike in petroleum and fertiliser prices.

Farmers in many cases do not grow wheat to avoid cost of inputs and feel comfortable even with minimum possible per acre yield of cotton till December. In the next Kharif season they go for fresh cotton crop cultivation,” says a Mirpurkhas-based cotton grower Mir Zafarullah Talpur. He also reports similar sort of damages to cotton crop in other parts of Mirpurkhas region.

Amanullah Shah of Sanghar district says, “I have ploughed land afresh where germination on below 25 per cent area is affected.” He has cultivated cotton over 60-70 acres. Growers used seeds 506 and 121 that gave the required germination results,” he says. “We will fill the gaps where seed germination has been poor,” he says.

Under the existing circumstances the growers have no option but to go for late sowing of cotton crop. Niaz Hussain Bodani of Sanghar used Sitara 008 for the first time and it failed to give the required result on 13 acres out of 35 acres on early sowing. “Normally, we sow cotton in April, he says.

“Cotton requires moderate weather and preferably spring season. Abnormal recent weather conditions( when temperature remained unusually high during March) played a critical role in the germination of seed and consequently damaged the crop, he says.

High value agricultural products will comprise a growing share of world agricultural trade in the future – and cotton is no exception. Textile firms in many countries, particularly developed countries, are scaling back domestic processing in favor of buying intermediate products such as yarn and fabrics from countries that have competitive advantages in these stages of processing. This trend offers opportunities to the U.S. cotton textile industry that, although cost-competitive in some stages of processing, has traditionally held a small share of world trade in manufactured cotton products.

High value agricultural products will comprise a growing share of world agricultural trade in the future – and cotton is no exception. Textile firms in many countries, particularly developed countries, are scaling back domestic processing in favor of buying intermediate products such as yarn and fabrics from countries that have competitive advantages in these stages of processing. This trend offers opportunities to the U.S. cotton textile industry that, although cost-competitive in some stages of processing, has traditionally held a small share of world trade in manufactured cotton products. Life of millions of farmers is dependent on this crop, in addition to millions of people employed along the entire cotton value chain, from weaving to textile and garment exports The area under the cultivation of cotton crops has been increased significantly in the last 30 years - around 7.85 million acres in 2005-06 as compared to 7.2 million acres in 2002-03. Beside being the world’s fourth-largest cotton producer and the third largest exporter of raw cotton and a leading exporter of yarn in the world our yield per acres ranks 13th in the world; as a result Pakistan annually imports around 1.5-2.00 million bales of cotton to meet growing demand from local textile mills; therefore it has become vital for Pakistan to increase its yield per acre.

Life of millions of farmers is dependent on this crop, in addition to millions of people employed along the entire cotton value chain, from weaving to textile and garment exports The area under the cultivation of cotton crops has been increased significantly in the last 30 years - around 7.85 million acres in 2005-06 as compared to 7.2 million acres in 2002-03. Beside being the world’s fourth-largest cotton producer and the third largest exporter of raw cotton and a leading exporter of yarn in the world our yield per acres ranks 13th in the world; as a result Pakistan annually imports around 1.5-2.00 million bales of cotton to meet growing demand from local textile mills; therefore it has become vital for Pakistan to increase its yield per acre.  It is unfortunate that there is no proper cotton crop insurance system available in Pakistan, while government does not provide any support or subsidy to cotton growers for inputs - resulted in frustration and lack of motivation in cotton growers. Farmers are facing with a number of risks till marketing of their crops including unexpected factors like inflation, high price of energy, unfair competition and speculation in open market by big cotton buyers. Although, government claims that they have excellent micro-economy policy to improve the livelihood of farmers and elimination of poverty in rural area through bank-loans offered to the farmers, however, the interest rates are fairly high.

It is unfortunate that there is no proper cotton crop insurance system available in Pakistan, while government does not provide any support or subsidy to cotton growers for inputs - resulted in frustration and lack of motivation in cotton growers. Farmers are facing with a number of risks till marketing of their crops including unexpected factors like inflation, high price of energy, unfair competition and speculation in open market by big cotton buyers. Although, government claims that they have excellent micro-economy policy to improve the livelihood of farmers and elimination of poverty in rural area through bank-loans offered to the farmers, however, the interest rates are fairly high. Pakistan has already surpassed the major obstacle on its way to adapting to biotechnology by enacting the Biosafety Rules in April 2005. These rules setup legal requirements for import, export, transport, and handling of biological agents, genetic engineering organisms or vectors, seeds, crops and foods, besides setting conditions for the researchers; seeds developers and companies. Usually it takes two to three years to do proper assessment for any Biotech crops before its commercialization. Whereas, Pakistan Atomic energy Commission (PAEC) had sought special permission in 1997 from the Ministry of Environment under “Voluntary Code of Conduct for release of GMO into the environment” prepared by NIBGE; and it conducted, checked and analyzed many safety tests on various cotton varieties which contain gene of genetically modified organism called Bacillus thuringiensis (Bt), a bacterium that is deadly to the “Sundies”.

Pakistan has already surpassed the major obstacle on its way to adapting to biotechnology by enacting the Biosafety Rules in April 2005. These rules setup legal requirements for import, export, transport, and handling of biological agents, genetic engineering organisms or vectors, seeds, crops and foods, besides setting conditions for the researchers; seeds developers and companies. Usually it takes two to three years to do proper assessment for any Biotech crops before its commercialization. Whereas, Pakistan Atomic energy Commission (PAEC) had sought special permission in 1997 from the Ministry of Environment under “Voluntary Code of Conduct for release of GMO into the environment” prepared by NIBGE; and it conducted, checked and analyzed many safety tests on various cotton varieties which contain gene of genetically modified organism called Bacillus thuringiensis (Bt), a bacterium that is deadly to the “Sundies”.  Although germination of these Bt cotton seed varieties vary from 65 %, to 85 %, but mixing or impurities were less than 2 %. In the beginning overall attack of “Lashkari Sundi” “American Sundi” and other bollworms remained low as compared to previous years but attack of sucking pests like Jassid, Whitefly, Thrips and other Aphid were high in both Bt and non Bt cotton crops. No serious incidence of cotton leaf curl virus disease was reported in Bt cotton varieties. Heat stress in cotton crop was also recorded in different region, however no stress was observed in Bt cotton varieties. Army, Pink and Spotted bollworm were active from July to October with peak infestation during September but Army remained in the field after spray for limited time period; IR-901, IR 448 and NIBGE 2 with minimum damage was recorded as compare to non Bt cotton crops. It is worth mentioning that infestation of American, Pink and Spotted sundies remained significantly low throughout the season in Bt varieties as compare to infestation in non Bt cotton varieties. Maximum alive larvae of Army, pink and spotted bollworm were recorded in fields of non Bt varieties around 7-8 per 15 plants while only larvae of Army bollworm were recorded in IR- 448, IR 901 and NIBGE-1 around 3 – 4 larvae in 15 plants. It is also important that newly hatched Helicoverpa Armigera when eat leaves of the Bt cotton crops died after few days; no larvae reached to pupal stage while in non Bt it has developed into pupa. Significant number of spray has decline in Bt cotton varieties; 4 – 5 applications as compare to non Bt cotton crop 6 – 9; most of spray were used to control sucking pests; however in chewing; pests spray was required to control Lashkari sundi. Although Bt cotton also provides significant control of targeted bollworms but supplemental foliar insecticide sprays are occasionally required to keep other bollworms from causing excessive damage in Bt fields.

Although germination of these Bt cotton seed varieties vary from 65 %, to 85 %, but mixing or impurities were less than 2 %. In the beginning overall attack of “Lashkari Sundi” “American Sundi” and other bollworms remained low as compared to previous years but attack of sucking pests like Jassid, Whitefly, Thrips and other Aphid were high in both Bt and non Bt cotton crops. No serious incidence of cotton leaf curl virus disease was reported in Bt cotton varieties. Heat stress in cotton crop was also recorded in different region, however no stress was observed in Bt cotton varieties. Army, Pink and Spotted bollworm were active from July to October with peak infestation during September but Army remained in the field after spray for limited time period; IR-901, IR 448 and NIBGE 2 with minimum damage was recorded as compare to non Bt cotton crops. It is worth mentioning that infestation of American, Pink and Spotted sundies remained significantly low throughout the season in Bt varieties as compare to infestation in non Bt cotton varieties. Maximum alive larvae of Army, pink and spotted bollworm were recorded in fields of non Bt varieties around 7-8 per 15 plants while only larvae of Army bollworm were recorded in IR- 448, IR 901 and NIBGE-1 around 3 – 4 larvae in 15 plants. It is also important that newly hatched Helicoverpa Armigera when eat leaves of the Bt cotton crops died after few days; no larvae reached to pupal stage while in non Bt it has developed into pupa. Significant number of spray has decline in Bt cotton varieties; 4 – 5 applications as compare to non Bt cotton crop 6 – 9; most of spray were used to control sucking pests; however in chewing; pests spray was required to control Lashkari sundi. Although Bt cotton also provides significant control of targeted bollworms but supplemental foliar insecticide sprays are occasionally required to keep other bollworms from causing excessive damage in Bt fields.  This translates into more than 30 percent increase in yield. It is noteworthy that in Bt cotton crops average number of cotton Bolls per plant are 120 while average Boll weight is app. 1.75 grams including seeds and number of plants per acre are as recommended by the department of agriculture. The economical gain by using Bt cotton per acre is more than Pak Rs. 3,000 at the market sale price of Rs. 1100/ Maund. In Pakistan average cotton grower has 10 acres of land; increase in such small income per acre would improve his quality of life. It is expected that cotton growers should have Bt seeds of the above varieties for at least 75,000 acres of land in year 2006-07.

This translates into more than 30 percent increase in yield. It is noteworthy that in Bt cotton crops average number of cotton Bolls per plant are 120 while average Boll weight is app. 1.75 grams including seeds and number of plants per acre are as recommended by the department of agriculture. The economical gain by using Bt cotton per acre is more than Pak Rs. 3,000 at the market sale price of Rs. 1100/ Maund. In Pakistan average cotton grower has 10 acres of land; increase in such small income per acre would improve his quality of life. It is expected that cotton growers should have Bt seeds of the above varieties for at least 75,000 acres of land in year 2006-07.  Bt seeds are highly dependent on agro climatic conditions, genotype of the variety and management of crop. In some areas, certain Bt varieties may be inappropriate for local growing conditions and may fail to produce satisfactory results. For example under high night temperatures and under hot dry conditions, bolls may drop off the plants. Therefore use only those approved Bt cottonseeds varieties; which are tested for your local agro-climatic conditions.

Bt seeds are highly dependent on agro climatic conditions, genotype of the variety and management of crop. In some areas, certain Bt varieties may be inappropriate for local growing conditions and may fail to produce satisfactory results. For example under high night temperatures and under hot dry conditions, bolls may drop off the plants. Therefore use only those approved Bt cottonseeds varieties; which are tested for your local agro-climatic conditions.